Challenge Group Wins "New Technology, New Product" Award in China Innovation Challenge

The 8th China Innovation Challenge Livestock Biotechnology Special Competition and the selection of "New Technology, New Product," jointly organized by the Ministry of Science and Technology and the Chongqing Science and Technology Bureau, and co-hosted by the National Pig Technology Innovation Center, Rongchang District People's Government, and Chongqing Livestock Science Institute, concluded successfully in 2023. Challenge Group's wholly-owned subsidiary and core enterprises were awarded in the open solicitation and expert evaluation.

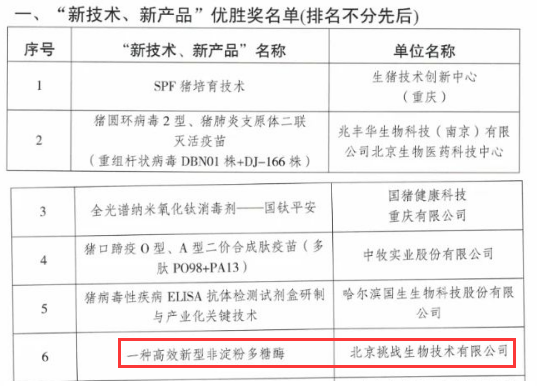

Challenge Group's wholly-owned subsidiary, Beijing Challenge Biotechnology Co., Ltd., won the "New Technology, New Product" Excellence Award for its "Highly Efficient Novel Non-Starch Polysaccharide Enzyme."

This product was developed by Beijing Challenge Group's research institute through a series of key technical breakthroughs, featuring a highly efficient novel enzyme preparation product with β-mannanase as the main component, possessing excellent enzymatic properties.

The β-mannanase full gene sequence ManT obtained through whole-genome synthesis can be stably and efficiently expressed in host cells. The recombinant strain produced by fermentation of β-mannanase exhibits strong resistance, with an enzyme activity retention rate of over 94% after pH 3.0 treatment for 30 minutes and over 92% retention rate after 3 minutes of water bath treatment at 80°C. Under in vitro simulated conditions, it can increase the digestion rate of soybean meal dry matter by more than 1.5 percentage points.

Under the conditions of the animal digestive tract, the product can efficiently degrade the anti-nutritional factor β-mannan polysaccharide in feed raw materials into mannose oligosaccharides. On the one hand, it reduces the anti-nutritional effect of mannose polysaccharide in the intestine, promotes the absorption of nutrients, improves feed nutrient utilization, and feed efficiency. On the other hand, it alleviates the immune-stimulating effect of β-mannan polysaccharide in feed raw materials such as soybean meal, thereby reducing the energy consumption of the animal body for immune stress. In addition, the degraded mannose oligosaccharides have a good intestinal health regulation function, promoting the proliferation of beneficial bacteria (such as bifidobacteria) in the animal intestinal tract and improving the balance of the intestinal flora.

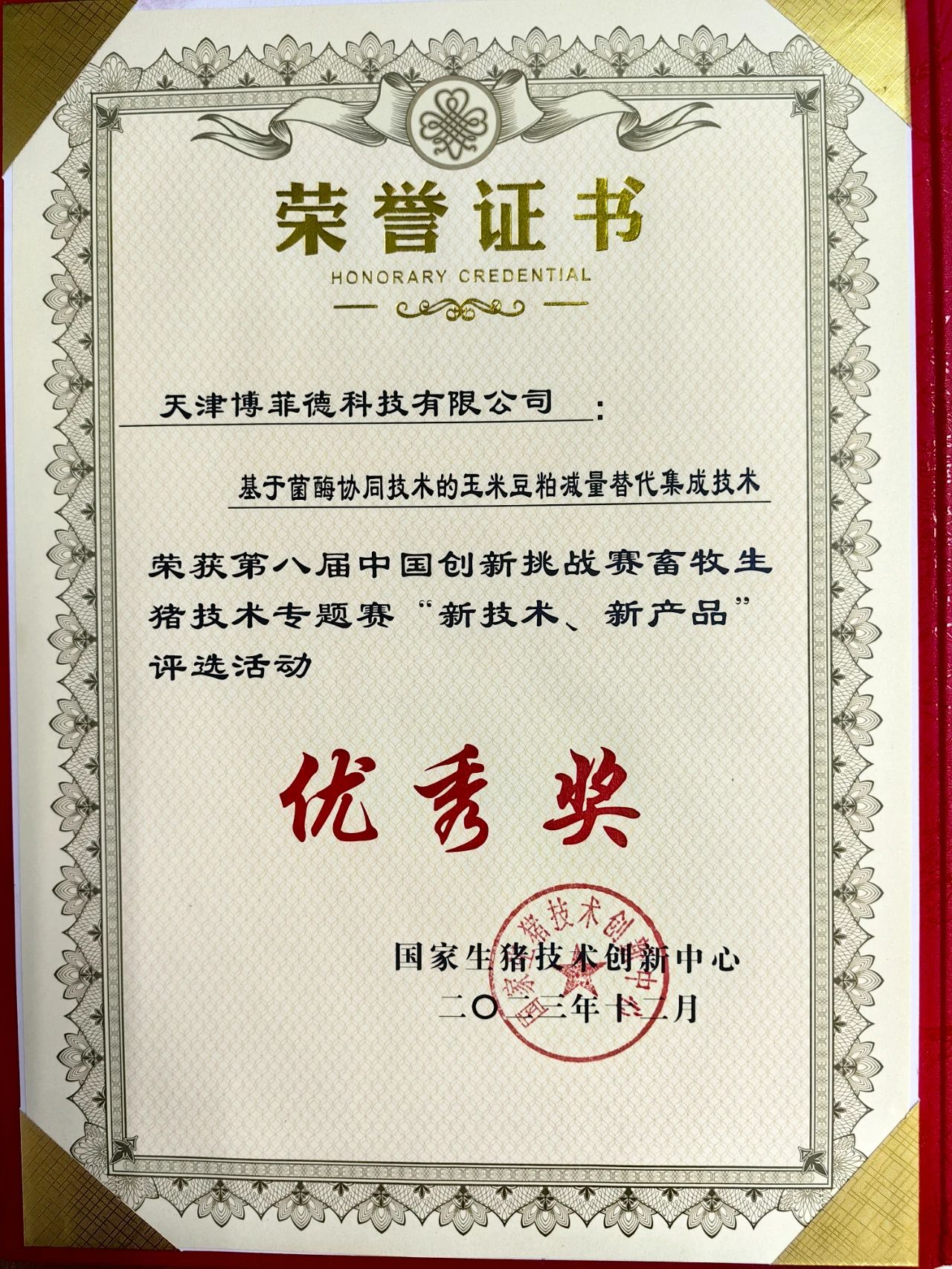

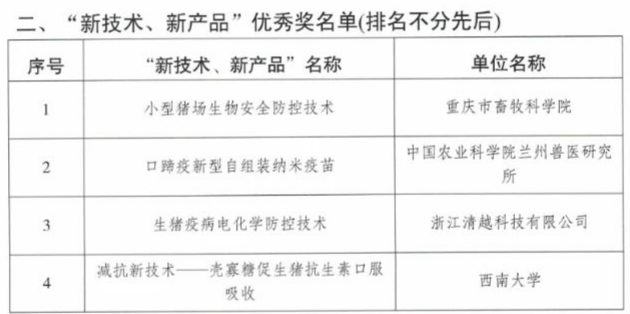

Challenge Group's core enterprise, Tianjin Biofeed Technology Co., Ltd., won the "New Technology, New Product" Excellence Award for its "Corn-Soybean Meal Reduction and Replacement Integrated Technology Based on Enzyme Synergy."

This technology focuses on key technological innovations in reducing and replacing corn-soybean meal, and through small-scale research and development and pilot-scale fermentation, it finally forms a mature industrialized solution. The main innovations are as follows:

(1) Development of high-resistant proteinase, with an enzyme activity retention rate of over 98% after pH 3.0 treatment for 30 minutes and an enzyme activity retention rate close to 90% after a 90-second water bath treatment at 75°C.

(2) Innovative particle-type enzyme preparation hot melt coating method. Compared with the traditional hot melt coating process, the coating time is shortened by 20%, and the particle coating is well-sealed, operationally safe, and convenient.

(3) Construction of a high-fiber biological fermentation feed quality evaluation system. Introducing microbial metabolites (lactic acid, ethanol) indicators, based on the principle of enzyme electrode technology, a rapid detection method for the content of lactic acid and ethanol in fermented feed is established, and a high-fiber biological fermentation feed quality scoring system is established.

(4) Development of a new series of high-fiber fermentation feed products. Applied in breeding production, it can save about 6.1% of corn, about 2.6% of soybean meal, increase piglet weight gain by 14%, increase egg production rate by 1.29%, reduce feed-to-egg ratio by 10.26%, and significantly improve intestinal health.

This technology meets the major industrial demands of the feed and breeding industry, with 5 authorized invention patents, 3 group standards, and 6 published papers. The related products and technologies have been successfully applied in breeding production, achieving significant economic and social benefits.